Vibrating Screen is a commonly used separation and filtration equipment in the oil industry. It separates particles of different sizes through vibration to achieve the purposes of purification, separation, and grading. Vibrating screens are mainly used in solid-liquid separation, liquid separation, and powder grading processes in industries such as oil, chemical, food, and pharmaceutical.

Specification:

Vibrating screens are usually classified according to the size of the screening surface and the size of the screening holes. Generally, the size of the vibrating screen's screening surface can range from several centimeters to several meters, and the size of the screening holes can be adjusted according to needs. In addition, parameters such as vibration frequency, amplitude, and screening surface angle can also be adjusted according to different process requirements.

Material:

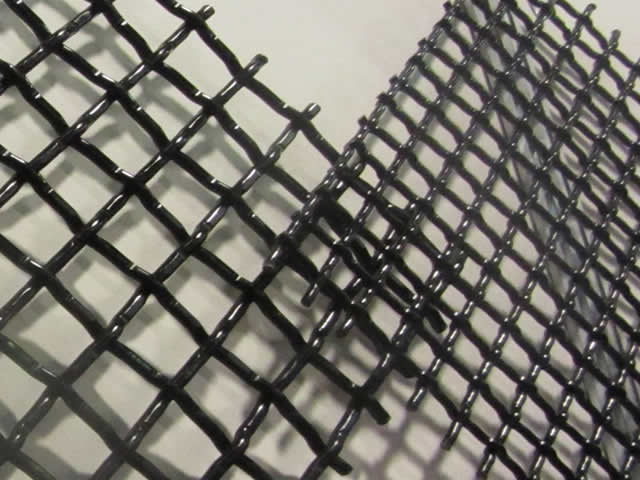

The material of the vibrating screen mainly depends on the material properties and use environment of the treated materials. Common materials include carbon steel, stainless steel, polyester mesh, etc. For extreme environments such as acid, alkali, high temperature, and high pressure commonly found in the oil industry, special materials such as 316L and Monel are widely used.

Classification:

Vibrating screens can be classified according to their structural characteristics, screening surface types, and applications.

According to structural characteristics, vibrating screens can be divided into vertical vibrating screens, horizontal vibrating screens, and rotating vibrating screens.

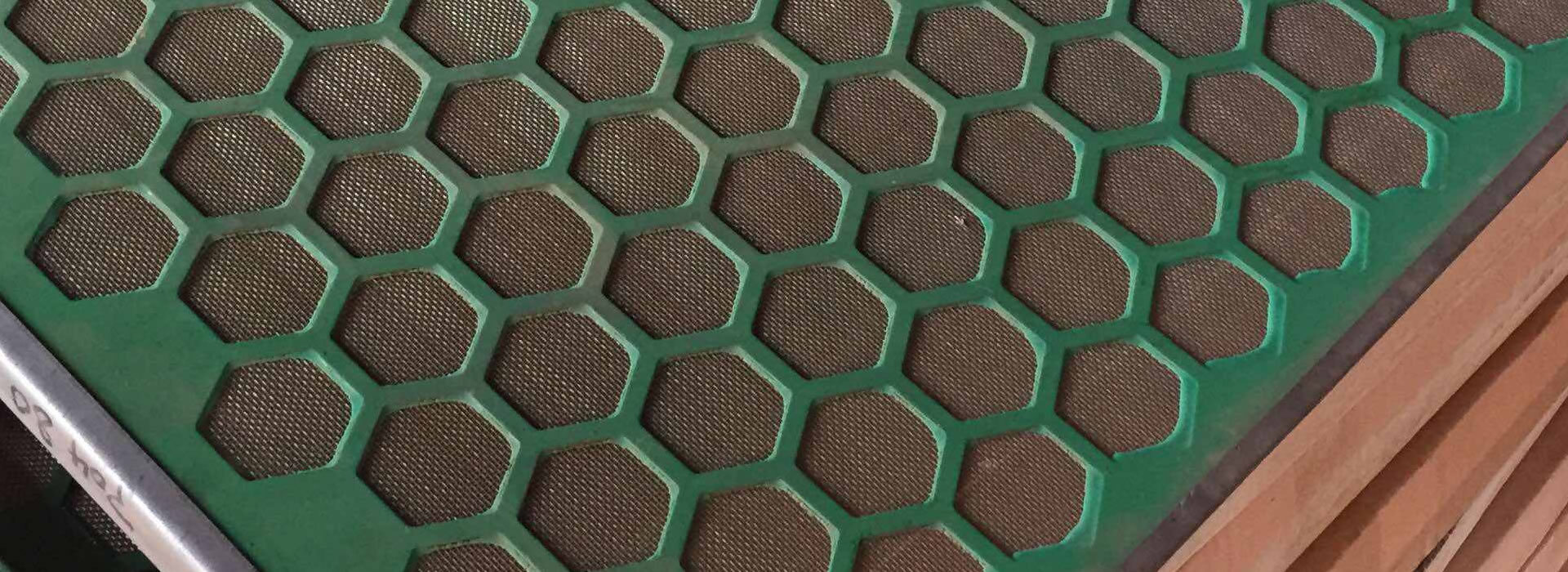

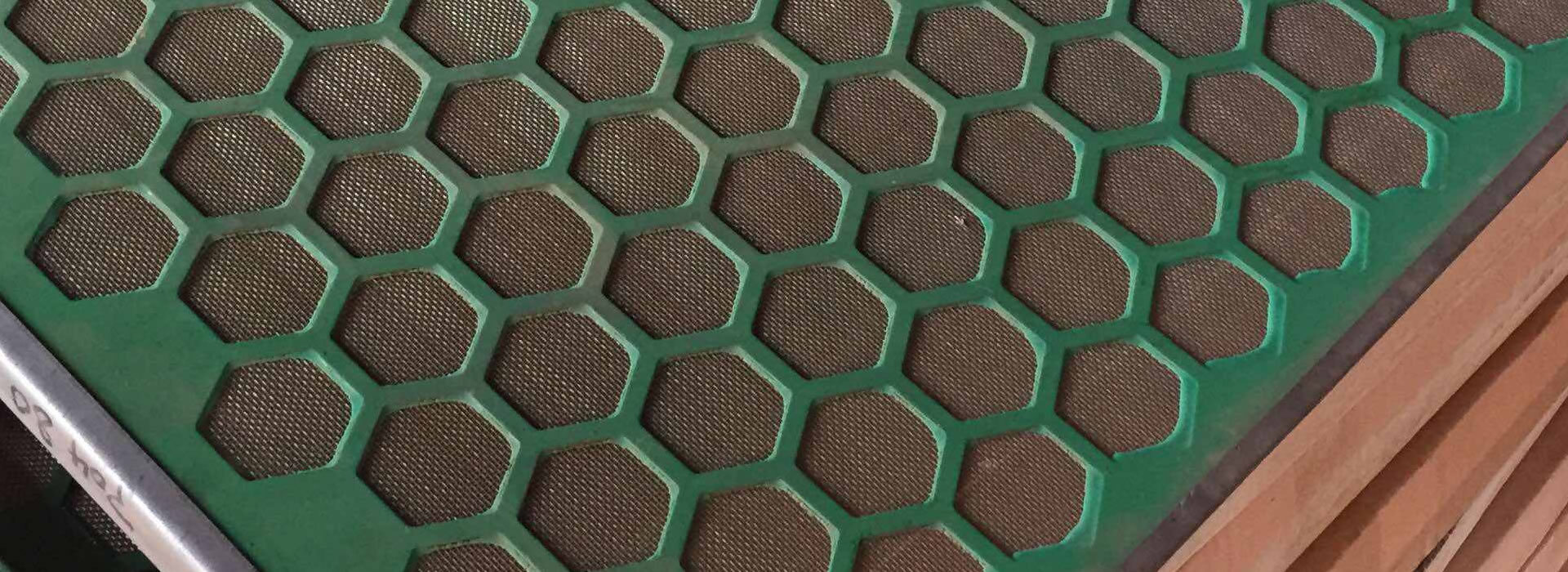

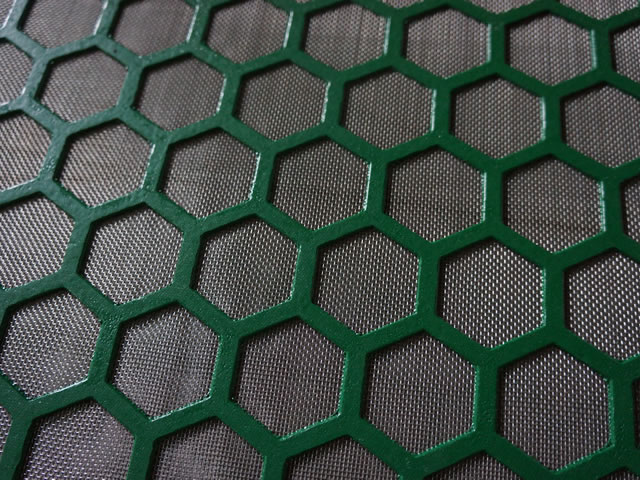

According to screening surface types, vibrating screens can be divided into woven screens, plate screens, mesh screens, etc. According to applications, vibrating screens can be divided into solid-liquid separation vibrating screens, liquid separation vibrating screens, and powder grading vibrating screens.

Characteristics:

High separation effect, which can effectively separate particles of different sizes.

High processing capacity, which can efficiently process large amounts of materials.

Strong adjustability, which can meet different process requirements by adjusting parameters such as vibration frequency, amplitude, and screening surface angle.

Easy to maintain and clean, which can ensure hygiene and safety during production processes.

Wide range of applications, which can be used in multiple industries such as oil, chemical, food, and pharmaceutical.

Application:

Vibrating screens are widely used in the oil industry for solid-liquid separation, liquid separation, and powder grading processes. They are an essential equipment for oilfield site construction, pipeline installation, tank cleaning, oil transportation and storage, oil refining processes, and other related processes.

Products Inquire